Research and Development on High-level Radioactive Waste and TRU waste

RWMC started research and development (R&D) on high-level radioactive waste(HLW) in development of a receiving system for returning HLW from the overseas reprocessing and feasibility study on management of HLW. Following these projects, we conducted research on long-term stability of geological structure necessary for geological disposal, study on operating system of geological disposal. In addition, we have been developing and providing appropriate technical information for national policy planning, as well as safety standards and regulation for HLW disposal.

After "the Designated Radioactive Waste Final Disposal Act" was enacted in 2000, Nuclear Waste Management Organization of Japan (NUMO), geological disposal implementing entity, was established to start siting process of geological repository. In response to this movement, RWMC has been conducting R&D on technologies necessary for the implementation of geological disposal project such as the design, construction and quality control of engineered barriers and other underground components, operation of the repository, retrieval after waste package emplacement by proceeding with basic tests, development of elemental technologies, engineering verification at actual scales, and development of analysis technologies. In addition, RWMC has been conducting fundamental research on important basic technologies with universities.

Regarding TRU waste, "the Designated Radioactive Waste Final Disposal Act" was amended to designate NUMO as an implementing entity of TRU waste disposal in 2007. RWMC also has been conducting R&D on conditioning and disposal concepts, disposal technologies, and study on basic phenomenon for performance assessment for TRU waste disposal.

Together with these research projects, we also have been conducting projects to promote understanding of geological disposal.

●indicates the ongoing projects

1. R&D on Engineering Technologies for HLW Disposal

- Remote welding technology of overpack lid closure and non-destructive inspection technology for overpack lid closure welds

- Manufacturing and emplacement technology of buffer materials

- Structural integrity and corrosion characteristics of overpack closure welds

- Study on re-saturation process of buffer materials

- Study on quality assurance and performance confirmation technology applied for disposal facility and development of monitoring equipments

- Development of technologies for retrievability

- Study on technical feasibility of disposal facility on the coastal area

Specimen for bentonite erosion test of buffer material at the underground research laboratory(URL)

State of the specimen after bentonite erosion test at the URL

From "Development of verified engineering technology for geological disposal"

Demonstration equipment of emplacement and retrieval

Backfilling test by spraying method

From "Research and development of advanced technology for reversibility and retrievability"

2. R&D on Engineering Technologies for TRU Waste Disposal

- Development of waste package with containment ability for the duration of several hundred year

- Study on gas migration behavior considering long-term alteration of cementitious and bentonitic materialsr

- Development of immobilization technique for anion nuclides(especially I-129) which has important effect in sefety assessmentr

- Study on release behavior of anionic nuclides(especially C-14)from activated metal waster

- Study on natural analogues of bentonitic materials

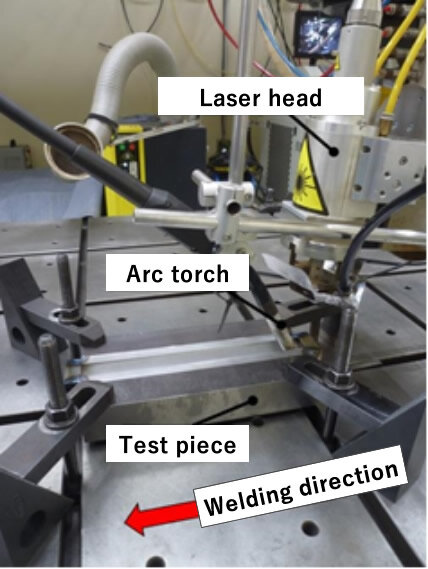

Test equipment of laser-arc hybrid welding for waste package

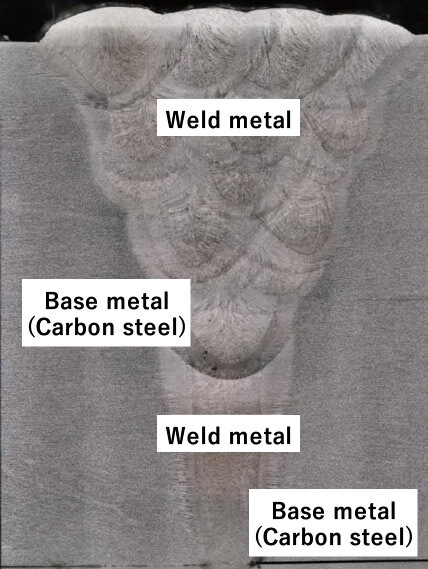

Cross section of test piece welded by laser-arc hybrid welding

From "Advanced technology development for geological disposal of TRU waste"

3. Research on Criteria and Standards

- Classification of TRU waste and safety assessment method

- Scenario in TRU waste disposal

- Safety standards of geological disposal

4. Promotion of Understanding for Disposal Technology

- Publishing brochures for public relation

- Open operation of the actual scale test facility to provide realizing, feeling and understanding disposal concept, engineering feasibility and long-term behavior of geological disposal

Explanation of engineered barrier system using the full-scale equipments and real material